DTF Washing Instructions⁚ A Comprehensive Guide

This guide provides a complete overview of how to properly wash DTF printed garments․ Learn about optimal detergent choices, machine settings, drying techniques, and ironing precautions to maintain vibrant prints and extend garment lifespan․ Proper care ensures your DTF designs remain beautiful․

Preparing Your DTF Garment for Washing

Before you toss your DTF-printed apparel into the washing machine, take a few crucial steps to protect your investment․ First, and most importantly, turn the garment inside out․ This simple action significantly reduces friction against the print during the wash cycle, preventing abrasion and premature wear․ Think of it as creating a protective barrier for your vibrant design․ Next, check all pockets for any loose items that could damage the fabric or the print during the wash․ Remove any items found and proceed with caution․ Button any buttons or zip up any zippers to prevent snagging․

By taking these preliminary steps, you’re minimizing the risk of damage and ensuring that your DTF print remains in pristine condition for many washes to come․ Remember, a little preparation goes a long way in preserving the quality and longevity of your DTF-decorated clothing․ These simple steps are key to maintaining the vibrant colors and sharp details of your DTF prints, ensuring they stay as stunning as the day you received them․

Choosing the Right Detergent and Water Type

The selection of detergent and water type significantly impacts the longevity of your DTF prints․ Harsh chemicals and minerals can damage the print, leading to fading and cracking․ Therefore, always opt for a mild, liquid detergent․ Avoid detergents containing bleach, as bleach is highly detrimental to the vibrancy of DTF designs․ Many people find that a gentle, fragrance-free detergent works best․ These are readily available at most grocery stores or online retailers․ The absence of harsh chemicals helps preserve the print’s integrity and prevents premature wear․

Regarding water type, soft water is preferable to hard water․ Hard water contains minerals that can build up on the fabric and potentially damage the print․ If you have hard water, consider using a water softener or a detergent specifically formulated for hard water․ Cold water is generally recommended as it’s gentler on both the fabric and the print, minimizing the risk of color fading or print damage․ By carefully considering your detergent and water choices, you’ll contribute significantly to the lasting beauty of your DTF-printed garments․

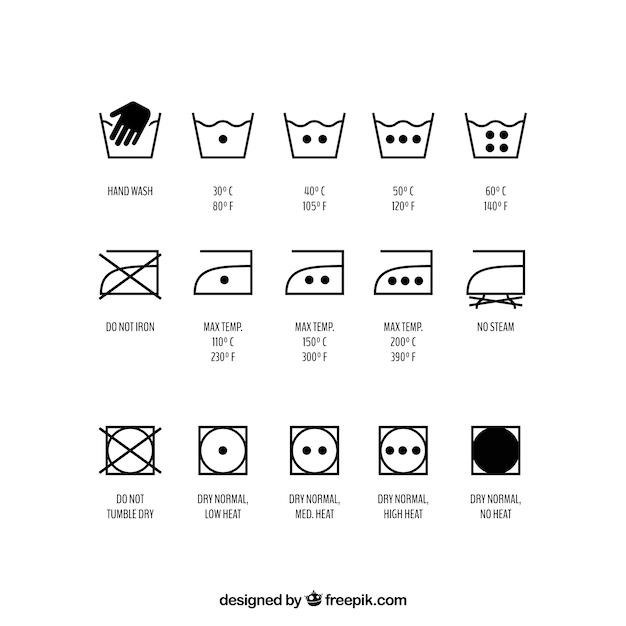

Optimal Washing Machine Settings

To ensure your DTF-printed garments retain their vibrancy and quality, selecting the appropriate washing machine settings is crucial․ Avoid overloading the machine, as this can lead to excessive friction and damage to the prints․ Always turn your garment inside out before washing to protect the delicate DTF transfer from direct abrasion during the wash cycle․ The inside-out method significantly minimizes friction against other clothes and the machine’s drum․

For the water temperature, choose cold water․ Cold water washing is the most gentle option and helps to prevent color fading and shrinking of the fabric․ Select the gentle or delicate cycle on your washing machine․ This cycle uses a slower spin speed and gentler agitation, reducing stress on the print and extending its lifespan․ Avoid using high-speed spin cycles, as the increased centrifugal force can damage the print․ Remember, a lower spin speed is key to preserving the quality of your DTF designs․ Following these guidelines will ensure your DTF prints stay vibrant and beautiful․

Drying Your DTF Printed Garment

After washing your DTF-printed garment, proper drying is essential to maintain the print’s quality and the garment’s shape․ Avoid harsh drying methods that could damage the delicate transfer․ The best approach is air drying․ To air dry, simply turn your garment inside out and hang it on a clothesline or drying rack in a well-ventilated area, away from direct sunlight․ Direct sunlight can cause fading and damage to the DTF print over time․ Allow the garment to dry completely before wearing or storing it․ Air drying is the gentlest and most effective way to preserve the vibrancy and longevity of your DTF design․

If you must use a machine dryer, select the lowest heat setting and a shorter drying cycle․ Even with a low heat setting, it’s still advisable to check the garment regularly to prevent over-drying․ Over-drying can cause the fabric to shrink and potentially damage the DTF print․ Remove the garment promptly once it’s dry to avoid unnecessary exposure to heat․ Always prioritize air drying for optimal results, but if machine drying is necessary, proceed with caution and closely monitor the process․ Remember, careful drying practices are vital for preserving the beauty and durability of your DTF-printed apparel․

Ironing DTF Prints⁚ Dos and Don’ts

Ironing DTF prints requires a delicate touch to avoid damaging the design․ Never iron directly onto the printed area․ The heat from the iron can melt or crack the DTF transfer, ruining the design․ If ironing is necessary, always iron on the reverse side of the garment, placing a thin cloth or pressing cloth between the iron and the fabric․ This protective barrier prevents direct heat contact with the print․ Use a low to medium heat setting on your iron; high heat can cause irreversible damage․ Test a small, inconspicuous area of the garment first to ensure the heat setting is appropriate for the fabric type․

Before ironing, make sure the garment is completely dry․ Ironing a damp garment can cause the print to become distorted or faded․ For best results, iron the garment inside out, focusing on smoothing out wrinkles away from the print․ Take your time and work in sections, applying gentle pressure to avoid damaging the fabric or the transfer․ If you notice any signs of damage to the print during ironing, stop immediately and reassess your technique․ Remember, prevention is key․ By following these guidelines, you can iron your DTF-printed garments while keeping the designs crisp and vibrant․

Understanding Fabric and Print Durability

The longevity of your DTF print is significantly influenced by the fabric’s composition and the quality of the printing process․ Natural fabrics like cotton and linen generally provide a more stable base for DTF transfers compared to synthetic materials like polyester or nylon․ Natural fibers tend to absorb inks more effectively, leading to better adhesion and resistance to fading․ Synthetic fabrics, however, can sometimes cause the transfer to peel or crack more easily with repeated washes or exposure to friction․ The weave of the fabric also matters; tighter weaves offer more support and protection for the print․

The quality of the DTF transfer itself is another critical factor․ High-quality transfers use durable inks and adhesives designed to withstand multiple washes and maintain vibrancy․ Low-quality transfers, on the other hand, may fade, crack, or peel after just a few washes․ Always choose reputable suppliers who utilize premium materials and techniques․ Proper application during the printing process is also crucial․ Inadequate adhesion can lead to premature print failure, regardless of fabric type or transfer quality․ Following the manufacturer’s instructions diligently throughout the entire process, from application to care, is essential for maximizing the lifespan of your DTF-printed garments․

Troubleshooting Common DTF Washing Issues

Despite careful washing, you might encounter issues with your DTF prints․ Fading is a common problem, often caused by using hot water, harsh detergents, or prolonged exposure to sunlight․ To prevent fading, always wash in cold water with a mild detergent and air dry your garments in a shaded area․ Cracking or peeling of the print can result from using high heat in the dryer or from the use of aggressive washing machine cycles․ To address this, always use a gentle or delicate cycle with low spin speed and avoid using the dryer altogether, opting instead for air drying․ If you notice the print is becoming stiff or rough, this might indicate a buildup of detergent residue․ Try rinsing the garment thoroughly after washing, or switch to a low-sudsing, eco-friendly detergent․

Shrinkage is another concern, particularly with certain fabrics․ Pre-washing the fabric before applying the DTF transfer can help minimize shrinkage․ Always check the care instructions for your specific fabric to confirm its wash temperature tolerance․ If you discover any discoloration or unusual staining around the print, it could indicate a reaction between the ink and the detergent․ Try using a different, milder detergent in future washes to resolve this․ By addressing these potential issues proactively and following the proper washing instructions, you can prolong the life and quality of your DTF prints․

Additional Tips for Long-Lasting DTF Prints

Beyond the basic washing instructions, several extra steps can significantly extend the life of your DTF prints․ Turning your garment inside out before washing is crucial․ This simple action protects the print from direct abrasion during the wash cycle, reducing the risk of wear and tear․ Avoid overcrowding your washing machine․ Overloading can lead to increased friction and potential damage to the print․ Give your garments plenty of room to move freely during the wash․ When drying, air drying is always the preferred method․ It’s the gentlest on the print and helps prevent fading and cracking caused by high heat․ If you must use a machine dryer, select the lowest heat setting possible and remove the garment promptly to minimize exposure to heat․

Consider the type of detergent you use․ Harsh chemicals and bleaches can damage the print over time, so always opt for a mild, gentle detergent specifically designed for colored clothing․ Avoid using fabric softeners, as these can leave residue that affects the vibrancy of the print and may cause stiffness․ Regularly inspect your DTF prints for any signs of wear or damage․ Catching minor issues early can help prevent them from becoming more significant problems․ With these extra precautions, you’ll ensure your DTF-printed apparel stays vibrant and beautiful for much longer․

Specific Instructions for Different Fabric Types

While the general DTF washing guidelines apply broadly, subtle adjustments are beneficial depending on the fabric’s composition․ For delicate fabrics like silk or lace, hand washing in cool water with a mild detergent is recommended․ Avoid any harsh scrubbing or wringing that could damage the fibers․ After washing, gently press the excess water out and lay the garment flat to dry․ For thicker, more durable fabrics such as cotton or linen, machine washing on a gentle cycle with cold water is usually suitable․ However, always check the garment’s care label for specific instructions, as certain fabrics may have limitations․ Synthetics like polyester or nylon often require a lower water temperature and a shorter wash cycle to prevent shrinking or damage․ Always err on the side of caution, opting for a gentler wash cycle whenever possible, especially for blends of different materials․ Remember, even with durable fabrics, turning the garment inside out before washing remains a key step to protect the DTF print from abrasion․

Regardless of the fabric type, avoid using bleach or harsh chemicals, and always air dry whenever feasible․ These extra precautions will ensure that your DTF print remains vibrant and your garment maintains its shape and quality, regardless of its composition․

The Importance of Waiting Before First Wash

Patience is key when it comes to preserving the longevity and vibrancy of your DTF-printed apparel․ Before subjecting your newly printed garment to the rigors of a washing machine, a waiting period is crucial․ This allows the DTF transfer to fully cure and adhere to the fabric․ The recommended waiting time varies, with some sources suggesting 24 hours, while others recommend a more conservative 48-hour period․ This time allows the ink to properly bond with the fibers, significantly reducing the risk of peeling, cracking, or premature fading․ Ignoring this crucial step can lead to significant damage to the print, rendering your garment less visually appealing and shortening its overall lifespan․ During this waiting period, resist the urge to wash or even handle the garment excessively, as any unnecessary friction could compromise the bond between the ink and fabric․ Think of this waiting period as an investment that will pay off in the form of a longer-lasting, more vibrant DTF print․ A little patience now saves considerable frustration and expense later․

By allowing the print to cure completely, you’re safeguarding your investment and ensuring your garment remains a cherished piece for much longer․

Addressing Specific Concerns Regarding DTF Care

Many have questions about caring for their DTF printed items, particularly regarding the longevity of the prints․ One common concern revolves around the number of washes a DTF print can withstand before showing significant wear․ While the exact number varies based on fabric type, print quality, and washing practices, sources suggest that with proper care, DTF transfers can endure 70 washes or more while maintaining vibrancy․ Another frequent question pertains to the handling of specific fabric types․ While the general guidelines apply to most fabrics, some may require additional care․ Always check the care instructions for the garment itself, as they may provide specific recommendations that complement the DTF print care instructions․ For example, delicate fabrics might necessitate hand washing or the use of a mesh laundry bag to prevent damage during machine washing․ Regarding color bleeding, using cold water and a gentle detergent helps minimize this risk․ Remember to always turn your garment inside out before washing to protect the print from abrasion during the wash cycle․ Finally, addressing concerns about ironing, it’s generally recommended to avoid ironing directly onto the print․ If ironing is necessary, use a low heat setting and place a protective cloth between the iron and the print․

0 Comments